Alan's background is comprised of 35 years in the electric utility field which

has included working as a lineman, an engineer, and his current position of

General Superintendent for the local Public Utility District. He is presently

undertaking a significant research project regarding the technical evolution of

the generation, transmission and distribution of electric power. This includes

construction methods, engineering practices, material specifications (including

insulators) and general operation. He also buys. sells and trades go-with items

including insulators, books, catalogs, apparatus, tools, etc.

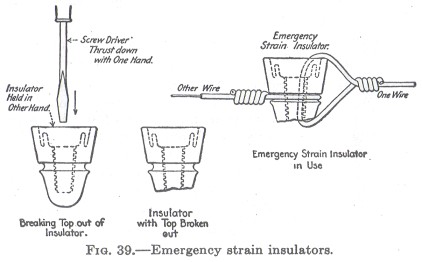

During my research I recently came across the following procedure in the

American Electricians' Handbook which I thought readers might have some interest

in. Improvising has always been a part of a lineman's way of dealing with

emergency repairs. It would seem to me that this procedure was in actuality

rarely utilized. Can you imagine a lineman using the procedure on a peacock blue

CD 162!?!

EMERGENCY STRAIN INSULATORS: These can be made by knocking the end out of

common glass line-wire insulators as illustrated in Fig. 39. To break out the

end, hold the insulator in one hand and strike the inside of the top a sharp

blow with the handle of a pair of pliers or with a screwdriver held in the other

hand. Where one insulator will not give sufficient insulation, two or more can

be used in series. Emergency strain insulators thus made are not strong enough

for heavy guy wires but more suitable for insertion in line wires.