A view from the factory floor.

In March 1975++, Kerr Glass Manufacturing Company decided to throw open

the doors to their Millville, New Jersey factory, allowing the general public to

enter and witness, firsthand, industrial glassmaking in action. During the open

house, Kerr CD 128 CSC insulators were being made. With camera in hand, my

father - Donald Wentzel - took advantage of this unprecedented opportunity to

photographically document as much of Kerr's insulator making process as was

accessible to public view. His photographs from the basis of this story.

A bit of background information is first required in order to make for better

understanding of the accompanying photos. Kerr's insulator forming

"I-D" machine was of circular design; it held twelve molds. Each of

the twelve mold positions was referred to by station number (1 through 12), with

station 12 being the point at which the insulator was removed from the machine.

My father was able to take pictures of the final three stations (10,11 & 12)

as well as a portion of the initial station (1). He could not film from the side

of the I-D machine where the molds were filled with molten glass, or

"charged". And, although the unphotographed side was where the bulk of

the molding took place, you will see that there were still a number of

interesting processes that occurred after an insulator had been molded into its

intended shape.

The I-D machine was powered by compressed air, with stations

advancing clockwise, rotating on a large geared base. This base is easily

visible in some of the photos. Smaller gears which drove the geared base were

interchangeable to allow altering the speed at which the machine advanced.

Manipulation of machine speed was dictated by three variables: insulator size,

glass temperature and production requirements.

Glass temperature for insulator

production in Millville was in the 1875 degree to 2050-degree range, depending

on the size of the insulator. Smaller insulators could be run hotter, and hotter

glass required the I-D machine to advance more rapidly.

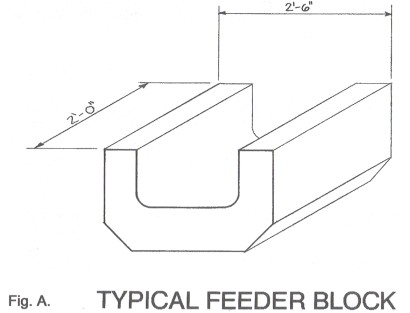

Glass made its way from

the furnace to the I-D machine by flowing through a channel comprised of a

series of "U' shaped refractory material [See Fig. A.]. At the end of this

channel assembly, known as a feeder in glasshouse terminology, molten glass

poured through a circular opening in the bottom of the last feeder block. This opening, called an orifice,

accepted a variety of refractory inserts known as orifice rings. The size of the

opening in the orifice ring determined the diameter of the stream of molten

glass exiting the feeder channel.

After passing through the orifice ring, the

glass stream was cut - or perhaps more accurately, interrupted - at precisely

timed intervals by a scissors-like mechanism. Regulated interruption of glass

flow, or "shearing", produced a piece of molten glass of known mass.

In the instance of a Kerr CSC, the mass required was 17 ounces. After shearing,

the molten mass, descriptively called a "gob", slid under force of

gravity down a polished cast aluminum chute. At the end of the chute, a hinged

deflector funneled the gob into an opening in the top of a waiting mold

assembly.

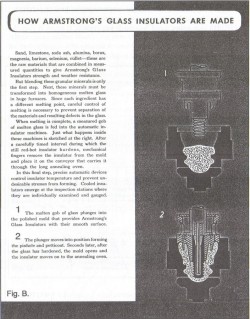

An Armstrong's advertisement reproduced here as Fig. B. serves as a

simple diagram of the molding processes previously described and not shown in

the accompanying photographs. In this advertisement, the dark "T"

shaped item at the very bottom of diagrams 1 and 2 is a stylized representation

of a mold bottom plate (more on that later). A "plunger" assembly is

depicted in a raised position in diagram 1 and as a cutaway view in its lowered

position in diagram 2. This assembly had provisions for forming all the inner

profiles of an insulator, including the threads in the pinhole cavity. Insulator

molding began with the plunger raised completely out of the mold, thereby

creating an opening through which a gob dropped into place.

Medium Image (112 Kb)

Large Image (247 Kb)

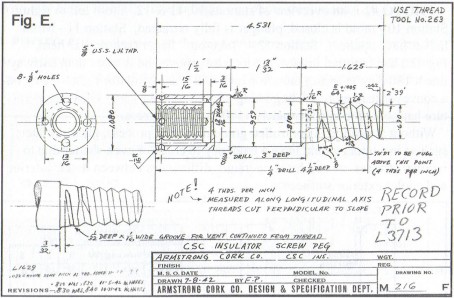

In the modem process of insulator molding as employed

by Kerr, it was necessary that the screwpeg, which molded the threads, be

twisted out of an insulator at the same pitch as the threads in order to

preserve the thread profile impressed in the hot glass. In contrast, the much

earlier Pennycuick process of screwpeg retraction relied upon a segmented

screwpeg, which could collapse inward upon itself, and could then be lifted

straight up out of the pinhole.

With that being said, it's time to begin our photographic tour.

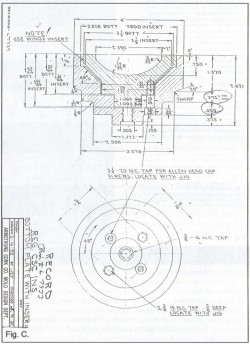

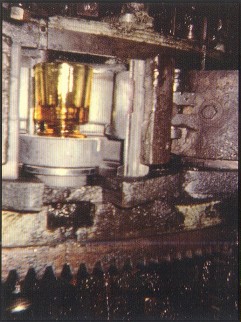

PHOTO #1 is a close-up of the next-to-last machine position, station 11. An

insulator sits upside down, resting only on its mold bottom plate, nearly ready

for removal from the I-D machine. A drawing of a virtually identical Armstrong's

CSC mold bottom plate is included as Fig. C.

Medium Image (86 Kb)

Large Image (179 Kb)

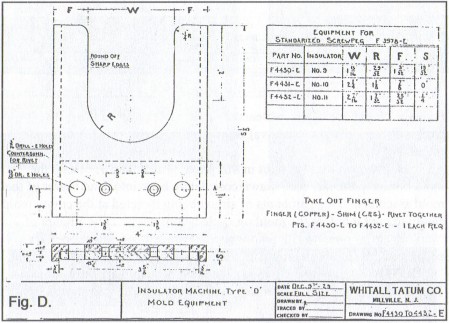

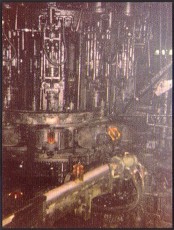

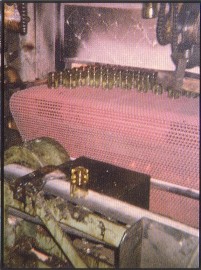

PHOTO #2 is an overview of stations 10, 11 & 12. From left to right:

Station 10 - mold is closed, plunger is fully retracted. Station 11 - Mold

halves have opened. Station 12 - "Take-out" finger (see similar item,

Fig. D.) has captured insulator at its wire groove and is more than halfway into

a 180 degree arcing motion which will place insulator right-side up on a

conveyor leading to the beginning of an annealing lehr. Glass temperature has

cooled to approximately 1100 to 1200 degrees.

Without annealing, a controlled

gradual cooling process, glass products such as insulators would have a tendency

to crack or even shatter due to internal stresses created by temperature

differences between hotter interior and cooler exterior surfaces.

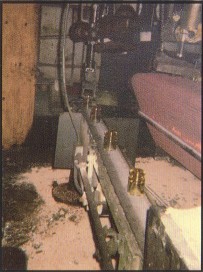

PHOTO # 3 is a close-up view of the transition from station 11 to station.

12. The mold bottom plate with its insulator in place is slowly being pushed

away from the centerline of the mold halves toward the outside edge of the I-D

machine. Note the carrier circuit threads visible on the screwpeg at the top

edge of the photo. A drawing of a virtually identical Armstrong's screwpeg is

shown in Fig. E.

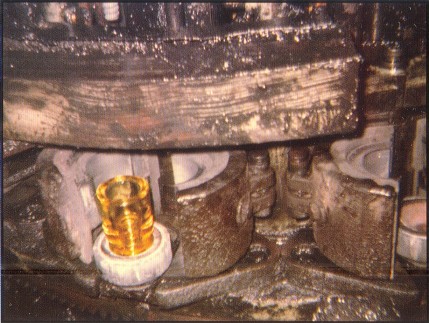

The take-out finger in the foreground of PHOTO #4 has just set

an insulator onto a transfer conveyor. The mold bottom plate in transition from

station 11 to station 12 has advanced about 1/2" closer to the perimeter of

the machine than shown in Photo #3. As the mold assembly rotates toward station

12, the mold bottom plate is extended outward and away from the mold halves until it clears the outermost limits of the mold casing,

thereby enabling removal from the I-D machine by the take-out finger.

The empty

open mold at right in this photo is at station 1. Here, the mold bottom plate

has been drawn completely back into dead center of the mold assembly. Huge

amounts of air are being directed at the empty mold cavity to cool it before the

molding cycle begins anew. The amount of "cooling air" applied to the

mold was adjustable; the machine operator could tweak it for optimum production.

PHOTO # 5, an overview, shows the mold bottom plate fully extended. The take-out

finger (difficult to see in this view - it's angled approx. 45 degrees to the

right) is returning to nestle into the wire groove of an approaching upside down

CSC.

Taken just seconds after the previous picture, PHOTO #6 finds the take-out

finger (angled approx. 80 degrees to the left) nearly in position to secure the

advancing CSC in its specially designed "U" shaped groove.

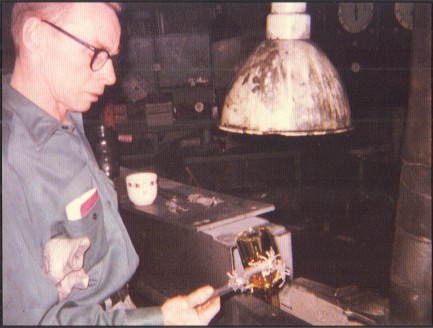

Generally

speaking, automatic insulator production at Kerr required little or no manual

intervention. It is quite possible that the machine operator in PHOTO #7 is just

showing off for the camera, however, there is something of much greater interest

to note in this picture. Above the operators extended arm can be seen the

brilliant glow of a gob sliding downward toward an awaiting mold.

PHOTO #8 shows

a still incandescent, yellow-hot insulator which has traveled about three feet

toward an annealing lehr after being deposited on a transfer conveyor by the

take-out finger.

KERR INSULATOR PRODUCTION - A view from the factory floor.

Photo 1. Close up of station 11.

Photo 2. Overview of stations 10, 11 and 12.

Photo 3. Close up view of the transition from station 11 to station 12.

Photo 4. Take-out finger in foreground has just set

an insulator onto a

transfer conveyor.

Photo 5. Shows the mold bottom plate fully extended.

Photo 6. Taken just seconds after Photo 5.,

the take-out finger nearly in

position

to secure advancing insulator.

Photo 7. Machine operator.

Photo 8. Still incandescent, yellow-hot insulator.

Photo 9. Mold bottom plate, with insulator in

place, is nearing full outward extension.

Photo 10. Group of insulators as they approach

the point of transfer to

an annealing lehr conveyor.

Photo 11. Insulator stopped at end

of the transfer conveyer.

Photo 12. Woven asbestos cloth covers the end of a pair of tongs

used for

visual inspection of hot insulators.

In PHOTO #9, the mold bottom plate, with insulator in place, is nearing full

outward extension. A close comparison of this close-up with the overview in

Photo #5 reveals that the mold bottom plate is about 3/4" short of full

extension. In the right rear of this picture at station 1, an empty mold bottom

plate is in the process of retracting toward its molding position in the center

of the mold halves.

In PHOTO #10, the photographer has turned away from the I-D

machine to film insulators as they approach the point of transfer to an

annealing lehr conveyor. Note the insulator in mid transfer at the top right

comer of the picture.

The insulator stopped at the end of the transfer conveyor

in PHOTO #11 has been grabbed at the wire groove by a swing-arm mechanism in

preparation for lifting to a conveyor that will carry the hot insulators through

an annealing lehr. A careful scan of the floor on either side of the transfer

conveyor reveals the fate of a few unlucky brethren. Eight to twelve hours after

entering the box-like structure of the lehr, the insulators will emerge for

packing, having been cooled to room temperature.

PHOTO #12 Woven asbestos cloth

covers the end of a pair of tongs used for visual inspection of hot insulators.

- - - - - - - - - - - - -

As a fitting finale to this photo-documentary, there is an amusing anecdote

that arose from the 1976 open house.

Kerr management had elected to give away CSC insulators as souvenirs of

the open house tours. One woman, upon being presented her insulator,

graciously handed it back, and asked if she could have one like she had seen

being made. A puzzled plant employee explained that the insulator in his hand

was exactly like those she had just seen. Exactly the same. Identical!

"No, it isn't," the woman insisted, and pointed back toward

the take-out transfer conveyor, still moving a steady stream of incandescent

1100 degree insulators. "I want one of those," she said, adding with

emphasis, "I want one of the yellow ones!"

The truth be told, at the temperatures maintained for glass insulator

production, it was virtually impossible to tell what color the glass would be

when it cooled. All colors look yellow or orange when they're molten. But that

knowledge didn't prevent the old-timers at Kerr from getting a good chuckle over

the woman's comment.