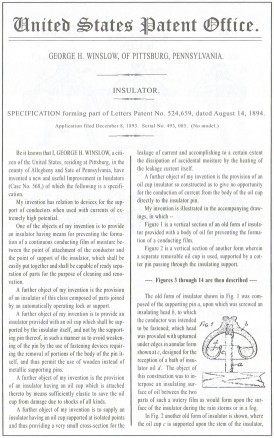

Mac's Believe It or Not!

by John McDougald

Reprinted from "Crown Jewels of the Wire", May 2002, page 25

TWIN PIN

CD 138.9

Although several decades ago several Twin Pin insulators were located by the

Millers of Michigan many years ago, there has never been any patent information found

regarding the insulator.

Current owner of the only mint unit, Tommy

Bolack, speculates that the "standard pin" attached the insulator in

the normal manner to a structure and that the "side car" appendage may

have served as a connection for a dry spot or fuse of some kind. The threading

of this part of the insulator is non-standard.

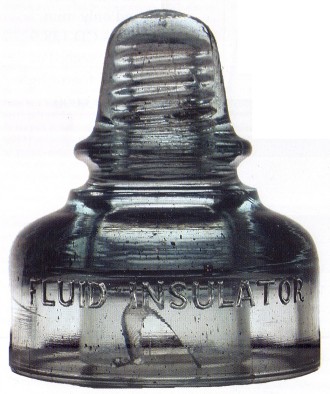

LIQUID INSULATOR, CD 180, and

FLUID INSULATOR, CD 180.5

Two of the oxymoron insulator names are the "Liquid" and the "Fluid". The are

named as such since they were designed to eliminate anything "wet"

during installation by using a reservoir of oil.

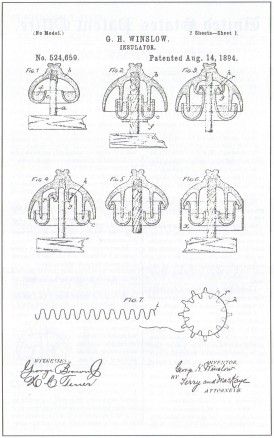

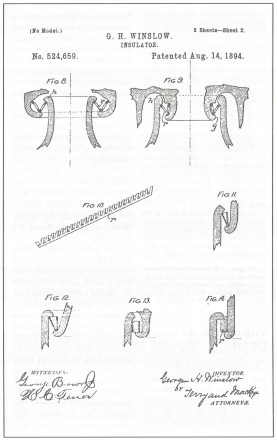

Although no specific patent

information has been found that covers the specific designs of the CD 180

"Liquid" and the CD 180.1 "Fluid", there was a reference to

both of these styles in a patent that was filed August 14, 1894 by George H.

Winslow of Pittsburgh, Pennsylvania.

As of this writing, I am not aware of any

trade journals that contained advertising or descriptions of the

"Liquid" insulator. However, a catalogue from March 1892 does contain

a beautiful lithograph illustration of the "Fluid Insulator" along

with the following descriptive information regarding its use:

|

FLUID INSULATOR

The insulator supports of an overhead line are the most vital points of

importance to the insulation resistance of the entire line, and those that are

the most advanced in electric light and power work have learned from experience

the economy of carefully insulating the line to prevent the leakage of current.

The Fluid Insulators are especially designed to prevent surface leakage, and to

give an insulation many hundred times higher than that obtained from the

ordinary forms of glass insulators now in use. An insulating fluid, which is not

sufficiently dense to support even a film of dust or moisture, is placed in a

recess formed in the glass, and well protected from the weather. In this way a

fluid surface, which is always clean and highly insulating, even in the dampest

weather, is interposed between "line" and "earth." It can be

readily observed that, although the first outlay for these insulators may be

greater than that of ordinary glass insulators, the subsequent saving in running

expenses and the avoidance of trouble from leakage, especially in rainy weather,

will more than repay first expenses within a very short time.

In power

transmission, where it is desired to transmit heavy currents of high

electro-motive

force, the use of Fluid Insulators is an absolute necessity to success. In

connection with this we would call attention to Prof. Badt's Electric

Transmission Handbook, and particularly to the test of Prof. Weber mentioned on

page 51.

The "Insulation Fluid' will not freeze, evaporate, nor creep like

paraffin or mineral oils, and will last three or four years even in a hot

climate. It is, therefore, advisable to use the Fluid intended for the insulator

and not cheap substitutes.

A conception of the value of Fluid Insulators may be

gathered from the fact that at the present time they are in use all over the

world by various governments, telegraph, telephone and electric light and power

companies, but nevertheless, although foreign companies have been using them for

over twelve years, and their insulating properties have become a matter of

record, they have not heretofore been extensively adopted in the United States,

principally on account of the less care used in these matters by people in this

country and their advance in price over those commonly in use. In placing them

before the electrical public we appeal to the intelligence of the purchaser

rather than to his preconceived ideas of economy, and feel confident that if

these insulators are once adopted their record will justify our claims for their

excellence and our confidence in the intelligence of the purchaser.

Experience

has demonstrated that for pressures of over 400 volts the electric light

purchaser can not afford to use any but the Fluid Insulators. The following test

may be of interest:

Twenty ordinary and twenty oil insulators were placed on

poles in the usual manner, and during three years constant observations gave the

following result:

20 Fluid Insulators == 12.960 Megohms==each 259.2 Megohms

20

ordinary " == .222

" ==

" 4.4 "

925.. Fluid Insulators, only (Glass)- - - - - - - - - - - - - per 1,000,

$400.00

925

P. Special Locust Pins - - - - - - - - - - - - - - - - - - -"

" $50.00

925

C.Spring Cotters for Pins - - - - - - - - - - - - - - - - - "

" $40.00

925 F.

Fluid (30 gal. sufficient for 1,000) - - - - - - - - - " 30 gal.

$30.00

Illustrated Catalogue of Electric Light and Power Supplies ,The Electrical

Supply Co. No 23 Third Edition, March 1892. page 50.

|

Medium Image (131 Kb)

Large Image (294 Kb)

Medium Image (89 Kb)

Large Image (200 Kb)

Medium Image (76 Kb)

Large Image (169 Kb)

Medium Image (55 Kb)

Large Image (119 Kb)

THE DRY SPOT CD 182

Last summer when Mrs. Mac and I visited the Smithsonian Institution, Nance

Briscoe who works in the Electricity Division, had put out an "all points

insulator bulletin" to all Smithsonian departments to send any insulators located throughout their

museum complex to the department of electricity.

Her roundup call netted two

insulators....a 8" long porcelain strain insulator and this CD 182 Whitall

Tatum Dry Spot. The great thing about this piece was its wires and Leverite were

intact showing exactly how this insulator was installed.

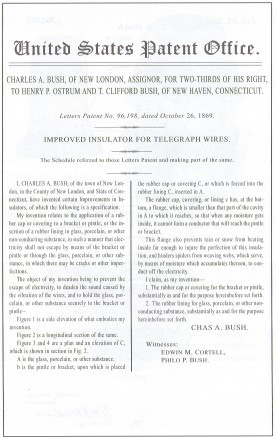

THE BUSH THREADLESS LINER

Owner Tom Moulton of this most unique item shares the following:

The piece

came from Poughkeepsie, New York from a utility lineman who had a small

collection which he shared with me from time to time, when I traveled to

Poughkeepsie as a lighting sales engineer for Holophane Lighting. Time frame was

early to mid 70's. I missed seeing him for several visits and finally found out

that he had died suddenly. His wife contacted me at some later period and sold

his small collection to me. I remember that when I got it, it was unwrapped and in buckets in their garage.

At one time, he had two threadless

pieces which never got to me. At any rate, in one of the buckets was the Bush

piece...I did not know what it was and almost tossed it out but it found a place

on one of my shelves. At some later date, I was wandering through the

"Collection of Insulator Patents - Issued by the US Patent Office 1881-1885" compiled by Aubrey and Penelope Branham in 1972 and spotted the

drawing. I do not remember if it was then or sometime later when I picked up the

piece that it dawned on me what it could be and it has been in my cabinet ever

since.

All who look at it sort of "overlook it" until I point out what

it is...and I have never seen another. I believe Jack Riesselman said that he

had and that it was in the collection of John Wilson. When I sold my collection in 1988, it went right past

the buyers as they were packing the boxes, so its kind of an unimpressive item.

Of course age has taken its toll and whatever elasticity it had when

manufactured is gone...but then it is probably 130 plus years old...and I know

that at 70, a good deal of my elasticity has gone as well.

The number 3 is

embossed on the top of the pinhole...I have no idea what the significance of

that is... could be that there were different sizes but it had to be done

intentionally.

A special thank you to Tommy Bolack and Tom Moulton for sharing insulators

from their collections for this month's color insert.

Next month -- "Holy Haley!" -- Believe It Or Not!

Medium Image (151 Kb)

Large Image (331 Kb)

The Twin Pin - This unique and only mint example of a CD 138.9

still holds

the record of the most paid for a single insulator -- $33,000.

The CD 180 Liquid Insulator design provided a reservoir

which was and

extension of glass molded as its base to hold oil

to prevent the leakage of

electricity.

The CD 180.5 Fluid Insulator came with a second piece, a cup,

which slid over

the pin and held the oil.

CD 182 Dry Spot Insulator No. 10

THREADLESS FIND: If time hadn't caused this rubber cover/liner

for a threadless insulator to harden and become brittle, it could be placed

inside the pinhole of this CD 731 S. McKee & Co. or similar threadless.

Being pliable, the rubber would conform to most irregularities found in size of shape of early threadless insulators.

The patentee, Charles A. Bush, also indicated it could be installed to cover

the threadless pin prior to placing the glass or porcelain insulator on in

position.

Medium Image (88 Kb)

Large Image (193 Kb)

Medium Image (112 Kb)

Large Image (250 Kb)

Medium Image (79 Kb)

Large Image (189 Kb)

|