Porcelain Insulator News

by Elton Gish

Reprinted from "Crown Jewels of the Wire", July 2002, page 15

Nearly all that has been discussed in Porcelain Insulator News since Jack Tod

started this column in 1972 has been about pin-type porcelain insulators. There

are many other interesting porcelain insulators such as standard porcelain. This

category is composed primarily of knobs and spools as the direct result of the

founding of the Underwriters' Laboratories, Inc. in 1894 by National Board of

Fire Underwriters to formulate safety standards for the industry. Prior to that

time, wood was commonly used for house wiring attachments in the form of knobs,

cleats, fuse holders, switches, lamp sockets, ceiling rosettes, etc. You can

imagine the fire hazard wood posed. By 1891, insurance companies would not

tolerate the use of wooden wiring insulators because of the fire hazard. The new

UL fire codes brought an abrupt end to the use of wood and pushed the porcelain

industry to the forefront for all electrical uses.

Many small electrical

porcelain companies sprung up in the early 1890's to make wiring insulators. The

National Electrical Code was published in 1897, which included standards for

electrical porcelain insulators used for "over-surface" wiring. This

is common house wiring that ran over rafters and through studs and walls.

Initially the code was set up for two-wire cleats and tubes. Then a vast array

of standard porcelain in the form of spools and knobs was numbered from 00 to

62. Additional styles were added such as No. 5-1/2 and No. 9-1/2. Any wiring

insulator outside the standard styles was referred to as "specialty

porcelain". Many patents cover cleats, tubes, and other specialty porcelain

designs. All of this is covered in great detail in Jack Tod's masterfully

researched book, The History of the Electrical Porcelain Industry in the United

States. It was published in 1977 and a few copies are still available for

purchase (www.r-infinity.com) .

The subject of this month's PIN is one small category of electrical wiring

insulators - wall tubes, and, more specifically, "glazed" wall tubes.

Most wall tubes were used to safely pass house wiring through rafters, studs, or

walls. As stated before, many small companies sprung up to make porcelain wiring

insulators. All of these small insulators were glazed, so it was a natural

progression to glaze wall tubes. Many of the earliest wall tubes were not

actually made of porcelain. They were made from a form of pottery that was

inherently brittle. The glaze acted to make the pottery stronger and more

durable and also improved the electrical characteristics, which wasn't all that

important for house wiring. Newer massed-produced wall tubes were made of

unglazed porcelain and, as such, will not be covered in this discussion in any

great detail. Unglazed wall tubes have little or no value to the collector

unless a desirable marking is associated with them such as "P&S".

Even then, values remain quite low. Pass & Seymour made the first wall

tubes out of porcelain starting around 1892 and continued using this material

for many years. Most of the ones I have seen have been unglazed.

One of the

earliest if not the first manufacturers of glazed wall tubes was the Akron

Smoking Pipe Co. (1890-1919) located at 3775 Mogadore Road in Mogadore, OH. It

started out as the E. R. Merrill Co., which produced "Ohio stoneware and

clay specialties". On September 3, 1890, the company was incorporated as

The Akron Smoking Pipe Co. (ASPCo) with offices on Falor Street in Akron, OH just west of Main Street in the same building as the Diamond Match Co. It

controlled the clay smoking pipe business of five other companies with directors

who owned the other companies.

ASPCo started making electrical porcelain in the

1895. In 1906, the company manufactured the first third rail insulators used in

the U.S., which went to the N.Y. Central Railroad. It produced all the original

insulators for the West Shore Line of the same railroad. Akron Smoking Pipe Co.

became Mogadore Insulator Co. in 1920 and The Akron Porcelain Co. in 1929

located in Kenmore, OH. In 1984, the company name was changed to The Akron

Porcelain & Plastics Co. with plant located on Cory Avenue in Akron, OH. In

1988, they opened a second plant in Barberton, OH and the company is still in

business after more than 110 years.

|

The logo is from the book, A Centennial

History Molding a Legacy: The Akron

Porcelain & Plastics Co., by Stephen H. Paschen (courtesy of Mike Lewis,

Pres.)

- - - - - - - - - - -

CLAY AND PORCELAIN GOODS.

The Akron Smoking Pipe: Company, of Mogadore, O., are extensively engaged

in the manufacture of all kinds of white and brown clay and porcelain

insulators, being a new department which this company have added to their business.

They make insulators in a variety of sizes running from one to twenty-tour

inches. with diameter from 5-16 to 1-3/4 inches. They also manufacture in the three

materials two styles of cleats which are designed to hold two wires, a complete

line of knobs suitable for all wiring purposes. such as telephone,

telegraph, street railway purposes, etc., and a line of specialties. They

solicit any specialty that is used In quantities that can be manufactured either

of porcelain or clay material, such as fuse boxes. switchboard plates; etc.

The article above was found in the September 2, 1896 Issue of The

Electrical Engineer.

|

The companies shown below also began making electrical porcelain in the

1890's. Dates are years the company was in business or years at that location:

Pass & Seymour, Inc. (Syracuse, NY; 1890)

American Marble and Toy Mfg.

Co. (27 W. Center, Akron; 1891 until fire in 1904)

The Columbia Insulator Co.

Akron Insulator & Marble Co. (until 1904 at 973 Grant in Akron, OH)

Colonial

Sign & Insulator Co. (1904 merger of Colonial Sign Co. and Akron I. &. M

Co.)

Empire China Works (???)

Brunt (G.F.) & Thompson (East Liverpool, OH;

1895-1897)

G. F. Brunt Porcelain Co. (East Liverpool, OH; 1897-1911)

Brunt

Porcelain Co. (Worthington, OH, a northern suburb of Columbus; 1914-1925)

Diamond Porcelain Co. (Trenton, NJ)

Star Porcelain Co. (Trenton, NJ; 1899-1907)

R. Thomas & Sons Co. (East Liverpool, OH; 1892-1927)

Imperial Porcelain

Works (Trenton, NJ; 1891-1ate 1930's)

There are many other porcelain companies that made standard porcelain and

specialty porcelain and some of the ones mentioned above may not have made

glazed wall tubes. Not much is known about glazed wall tubes because many are

unmarked, and it was a cheap item hidden away in walls for a century or more.

Glazed pottery tubes were a standard until just after 1900 when manufactures

began to offer unglazed porcelain tubes at a much lower price. Unglazed

porcelain tubes were probably easier to make with new modern machinery and

eliminated the troublesome fusing of the glazed tube to the firing tray and

resulting crude-looking irregular glazes that make glazed tubes attractive for

collectors. Porcelain tubes could be ordered fully glazed, too. The 1902 Central

Electric Co. catalog furnished unglazed porcelain tubes, and you could order

them glazed for an additional 50% per 100. A typical unglazed 6" long tube

with 1/2" opening was $5.44 per 100. By comparison, the same glazed .

"clay" (pottery) tube was $34.24 per 100. The difference in cost

quickly moved the customer to the unglazed porcelain tube. By 1912, Central

Electric had quit offering pottery tubes and carried only standard unglazed

porcelain tubes and glazed porcelain tubes for 50% more. As early as 1903, Brunt

offered only unglazed porcelain tubes. You can easily see why it is not easy to

find glazed pottery tubes today plus the fact that they are more brittle and

tend to break when removing from a wall stud. Pass & Seymour continued to

make both unglazed and glazed (50% more) porcelain tubes and never made the

inferior pottery tubes. They advertised that you could hammer their tubes in the

hole with a wooden mallet.

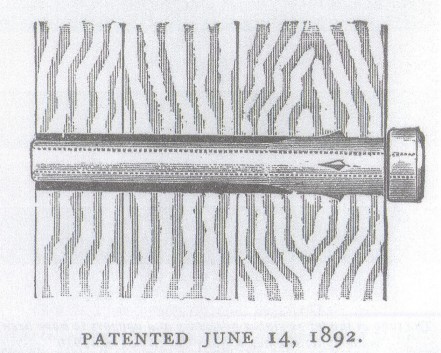

This advertisement was found in the

Electrical Review dated May 4, 1898.

(courtesy of Bob Stahr)

Very few manufacturers have been identified from glazed tubes in my

collection (I don't know of anyone else collecting glazed tubes). The following

markings are known:

A. S. P. CO. (Akron Smoking Pipe Co.) - embossed on either the tube or around

the tube below the head (glaze color: brown)

A. I. & M. CO. (Akron Insulator & Marble Co.) - either embossed ,

around the head or incuse on the tube (glaze color: both brown and gray-white)

A

M (American Marble & Toy Mfg. Co.) - deep incuse marking on end of the head

(glaze color: gray-white)

A M C (American Marble & Toy Mfg. Co.) - embossed

on the tube (glaze color: greenish-gray)

C (maybe Colonial Sign & Insulator

Co.) - incuse on the head (glaze color: gray-white)

S P CO (Superior Porcelain

Co.) - recess-embossed in an oval on the head (glaze color: gray-white)

(unattributed, most likely Star Porcelain Co.) - full-image incuse marking on

side of the head (glaze color gray-white) (unattributed, most likely Star Porcelain Co.) - full-image incuse marking on

side of the head (glaze color gray-white)

(unattributed) - long triangle

with slightly rounded points and base of triangle slightly bowed out (glaze

color: brown) (unattributed) - long triangle

with slightly rounded points and base of triangle slightly bowed out (glaze

color: brown)

(Diamond Porcelain Co.) - deep full-image incuse marking on side

of the head or struck on the tube (glaze color: both brown and off-white) (Diamond Porcelain Co.) - deep full-image incuse marking on side

of the head or struck on the tube (glaze color: both brown and off-white)

(Diamond Porcelain Co.) - very large incuse outline of the diamond on the tube

(glaze color: gray-white) (Diamond Porcelain Co.) - very large incuse outline of the diamond on the tube

(glaze color: gray-white)

Here are a few markings on unglazed porcelain tubes that are particularly

rare or difficult to find:

P & S (Pass & Seymour) - incuse or embossed on the tube

PAT JUNE 14

1892 (Pass & Seymour) - embossed on the tube. The patent is for the raised

barbs on the end of the tube to prevent the tube from being withdrawn from the

hole drilled in the wall stud or rafter.

A. P. CO. (Anderson Porcelain Co.) -

incuse marking on the tube

BRUNT (Brunt Porcelain Co.) - incuse marking on the

tube

D P CO (Davidson Porcelain Co.) - embossed marking on the head

E. P. CO.

(Electrical Porcelain Co.) - incuse marking on the tube

THOMAS (R. Thomas &

Sons Co.) - incuse marking on the tube

ELECTRICAL PORCELAIN CO. - incuse marking

on the tube E. LIVERPOOL, O.

I recently acquired a couple of wall tubes on Ebay that have a characteristic

early Thomas glaze mottled with dark mustard color. Imperial Porcelain Works was

one of the largest producers of cleats and may have also produced wall tubes.

The history of the American Marble & Toy Mfg. Co. and Akron Insulator & Marble Co. is sketchy

and confusing at this time, but we do know they made glazed tubes. The site of

the American Marble and Toy Mfg. Co. was dug a few years ago, and I did acquire

a variety of insulators found there including two long tubes (one glazed) with

deep incuse mark "A M" on the end of the head and two short unmarked

wall tubes with a light blue glaze with sponge-mottled darker blue. A few knobs

embossed with "A. I. & M. Co." were also found there, but I don't

know if both companies were associated in some way. AI&MCo was consolidated

with the Colonial Sign Co. in 1904 and AM&TMCo burned to the ground in 1904.

The two companies were located less than two miles from each other (on opposite

sides of IH-76).

A sample of small porcelain insulators found during a dig

at the American

Marble & Toy Mfg. Co.

Note that the cleat and one nail-knob are embossed

A.M. C.

I have several brown tubes made by Akron Insulator & Marble Co. embossed

with "A. I. & M. Co." around the square head and one with incuse

marking on the tube. There are also a few gray-white glazed tubes embossed

"A. M. C." on the length of the tube, but I have not seen a brown tube

with this marking. This marking is attributed to American Marble & Toy Mfg.

Co. from various insulators found at the dig.

Most "white" tubes have

a glaze color that is either gray-white, off-white, or greenish-gray in color. I

have only two pure white glazed pottery tubes. Of all the various sizes of tubes

offered in catalogs, there must be many other sizes one could find to add to

their collection. I mounted most of my collection on dowel rods fixed to a large board.

Tubes can be easily added or rearranged by sliding out the dowel. Below is a

photo of this set-up and photos of individual tubes. Often markings are

difficult to make out entirely, but if you can see a few of the letters, you

should be able to identify the complete marking. Adding a new glazed tube is a

slow process, which makes it especially rewarding when you do find one.

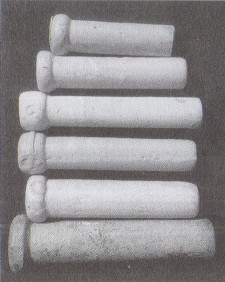

Collection of glazed and hard-to-find unglazed wall tubes

mounted on wooden

dowels attached to a large board.

The large tube at bottom has incuse marking "A. I. & M. Co. ".

The two above it are embossed with that marking around the head.

The tube at the

top is embossed "A S P CO" on the tube.

The tube at the top is embossed "A S P CO" around the tube

just

below the head. The next tube down has an incuse triangle

marking. The next two

have an incuse diamond marking and the

fourth tube is unmarked.

These four tubes are unmarked.

The tube at the top is glazed porcelain and

appears to have

been made by R. Thomas & Sons Co. circa 1905-1910.

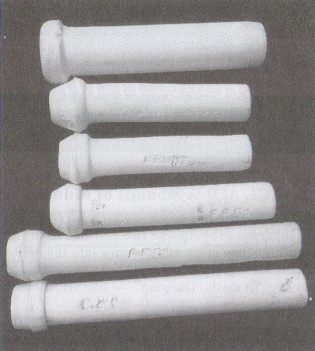

These five pottery tubes have various gray-white, off-white,

and

greenish-white glazes. The one at the top has an incuse

"star". The

next one down is embossed "A.I. & M. CO." on the

head. The middle

one is embossed "A M C" on the tube.

The last two are unmarked.

Illustration from the 1899 P&S catalog showing a wall

tube inserted in a

wall. The patent is for the projections on

the side of the tube that prevents the tube

from falling out.

They were made of "Syracuse China" and could be

hammered

in with a wooden mallet.

The six glazed pottery tubes above are all unmarked

except for one with

an incuse "C" on the head.

(See third tube from the top.)

The five of six tubes above are unglazed porcelain and have

various incuse

markings on the tube. The tube at the top is a

pure white glazed pottery tube.

|