The Hemingray No. 9

by Charlie Angevine

Reprinted from "INSULATORS - Crown Jewels of the Wire", July 1975, page 7

When I began collecting several years ago, I had no idea how many sizes, shapes and colors of insulators there

were. This was before I had my first insulator book or knew that there was such a thing as a club of insulator

collectors. After joining the Pole Cats, buying some books and attending some shows, one thing became clear to

me -- I

would never be able to have every different insulator I saw.

In January 1974 I was talking with Dennis McHenry, NIA Treasurer, about my problem. Dennis is a long time

collector and has nearly the entire Hemingray line. Within

his collection he has a specialty group of Hemingray 9, CD

106. At that time he had 38 of them, all different, and suggested that they would make a fine inexpensive

specialty for me. The thought of so many different insulators by one manufacturer, as well as the usually low

price, appealed to me. In February 1974 I began my specialty with a single insulator. Now the collection has

grown to 72 pieces, all different in one way or another.

Mr. N. R. Woodward, in his book of insulator history,

states that the Hemingray 9 was introduced about 1900 and

continued in production virtually unchanged until 1955, when it was redesigned. I believe that run of 55 years is

the longest production run of any insulator. I also believe that the 1955 redesign was quite major; and in

later years when CD numbers were assigned, the old 9 was given CD 106, and the new 9 was given CD 107. I have no

proof of these assumptions.

Perhaps the long production run accounts for the variety found in the 9. Perhaps some of it can be attributed to

the mold wearing over the years. Or perhaps different mold makers used some artistic license to create a slightly

different looking insulator. Someday perhaps I'll be able to answer some of these things. One person who may be able

to supply some of the answers is Mr. Ern Parkison of Muncie, Indiana. Mr. Parkison, who worked for Hemingray

for 41 years, has already been very helpful. Someday I hope to meet him in person and gather more information on

this fascinating subject.

That's enough background information. Now I'll get on to

explaining what makes the insulators different. The things I use to judge by are as follows: embossing, color, dome

size, skirt length, drip points, manufacturing defects and embossing errors.

I have recorded 8 different embossing arrangements. This is without counting mold and lot numbers. If they were

counted, there would be no end to the arrangements. The list of arrangements would be more interesting if they

were in chronological order. As it is, they are in random order:

- HEMINGRAY 9 // MADE IN U.S.A.

- HEMINGRAY / No 9 // PATENT / MAY 2 1893 (The 2 in this one is a script 2, like the old written Q.)

- HEMINGRAY / No 9 // PATENTED / MAY 2 1893

- HEMINGRAY / No 9 // PATENT / MAY 2 1893

- HEMINGRAY / No 9 PATENTED

- HEMINGRAY - 9 / 0 // MADE IN U.S.A. (The 0 on the front is an alpha 0 and indicates the insulator was made by Owens-Illinois, who bought out

Hemingray in 1933.)

- HEMINGRAY // No 9

- HEMINGRAY / MADE IN U.S.A. // No 9

Still on the subject of embossing, it should be noted that there are many different sizes of characters used. Sometimes there is more than one size

on a single insulator. In most cases, the embossing is very strong, regardless of the size.

I know that colors are seen differently by each person, but I feel I have recorded 14 different colors:

|

1. Clear |

8. A Darker Blue (almost teal) |

|

2. Near Clear |

9. Lime Green |

|

3. Straw |

10. Seven Up Green |

|

4. Pale Aqua |

11. Green Aqua |

|

5. Aqua |

12. Emerald Green |

|

6. Ice Blue |

13. Jade Milk Glass |

|

7. Normal Hemingray Blue |

14. Amethyst (various shades) |

After the embossing and colors, the next most apparent thing in looking at a group of 9's, is the dome size. This is the diameter of the upper ridge of

the wire groove. I have recorded 11 different sizes, ranging from 2-3/32"

to

2-7/16".

The next most apparent difference is the skirt length. This is the distance from the end of the threads to the base. I have recorded 19 different

lengths, ranging from 1/4" to 1-1/2".

The next difference is not nearly so apparent as the others, mainly because the insulator sits on them. Of course I mean the drip points. I

finally gave up trying to record different drip shapes, and settled on just two: sharp and round. However, I have recorded 17 different numbers of

drip points, ranging from 26 to 42. I also understand some 9's were made without drips, but I have not seen any.

Manufacturing defects are usually easy to spot. I count in this category mixed colors and any other abnormalities. I have recorded nine of these

defects:

- Amber swirl in Aqua.

- Amber swirl in Ice Blue.

- Jade swirl in Aqua.

- Hemingray Blue full of tiny bubbles.

- Ghosting of letters on crown, as if insulator fell back into the mold.

- Varied size of drips on same insulator, as if too little glass was used.

- Black streaks in Pale Aqua.

- Skirt not the same length all around, as if it settled to one side during cooling.

- Jade and Amber swirl in Aqua.

The last difference is the embossing errors. These are usually easy to

spot, but sometimes they do take considerable looking. I have recorded six embossing errors:

- 'N' in Hemingray was overstruck with a 'G'.

- 'D' in Patented was omitted.

- 'M' in Hemingray was double struck.

- 'ED' in Patented was omitted.

- 'HEMINGRAY / No 9' embossed over an attempt to blot out PATENT / MAY 2 1893.

- 'M' in Hemingray was overstruck with an 'I'.

Sorry to have been so long winded, but I guess my 72 insulators have quite a story to tell. Thanks for inviting me to tell as much of the story

as I

know or can guess. Perhaps someday I'll be able to add to it.

In the meantime, I would be glad to hear from anyone who has any information relating to the Hemingray 9. I am also interested in buying or

trading for any 9's that are different.

Thank you, Charlie Angevine, for your Hemingray No. 9 article. It reminded me of an article on early Hemingrays we ran in our second issue, April

1969, which was the first issue we ran out of. So, for the benefit of new collectors and subscribers, I thought perhaps a reprint would be nice. As

you read the following article on old Hemingrays, keep in mind that it was written in 1969, so there could be some difference in the rarity scale; but

basically it's a good article to help you with your collecting of early Hemingrays.

We hope these two articles may inspire someone to write one on Hemingrays not covered here.

Your Editor

EARLY HEMINGRAYS

by Bob Anderson

(Copied from pages 3 - 11 of April 1969 issue of this journal.)

As with old Brookfields little is known of the early Hemingrays except that a patent was issued December 19, 1871 to Robert Hemingray covering a

method of forming insulators. This report deals with insulators so embossed and a few with the May 2, 1893 patent (covering drip points)

which were continuations of earlier styles.

BACKGROUND

Before concentrating on Hemingray it might be interesting to look briefly at

why so many companies tried their hand at making insulators. Glass houses in

those days were fire traps, and there probably wasn't a pleasant job in the

place. Even so, as with many other lines of work, if the money was good, the job

could be tolerated at least for a while.

Telegraph building during the second half of the 19th century was a booming

business. For instance, in an address at the Morse Testimonial June 10, 1871

William Orton, then president of Western Union, stated that in the U.S. alone

there were 180, 000 miles of telegraph wire and among Europe, India, and

Australia another 475, 000 miles. Further, the industry as a whole was expanding

at the rate of 100,000 miles of wire per year. Another account lists nearly

290,000 miles of wire in the U.S. early in 1878. This adds up to a growth rate

of 17,000 miles per year in the U.S. alone between mid-1871 and 1878.

These lines needed insulators. If one assumes that poles were placed every

150 feet or about 35 poles per mile, then 35 insulators were needed per mile of

wire. A Tillotson catalog from sometime in the 1880's lists insulator prices at

$35 to $50 per thousand. Assuming an average price of $40 per thousand, one mile

of wire insulation cost about $1.50. Using the 17,000 mile per year growth rate

this meant someone was being paid over $25,000 per year to furnish insulation in

the U.S. alone.

While it is true that workers had to be paid and raw materials to make glass

had to be purchased from this gross amount, still $1 was worth about three times

what it is now; and there were very few taxes. It is not hard then to see why

people wanted to make insulators especially if they already had an established

glass house as did Hemingray.

According to Woodward's The Glass Insulator in America 1967 Report,

Hemingray glass started in 1848, the Covington Kentucky plant was in operation

by 1858, and in 1874 the name became Hemingray Glass Company with Robert

Hemingray president. A plant was built in Muncie, Indiana and began operation

around 1890 though it is not known whether or not they made insulators. The

Covington plant operated until 1919 when it was destroyed by flood, and the

Muncie plant operated through 1933 when it was sold to Owens-Illinois.

The insulators themselves are for the most part 3 part mold. Early models are

what I call old 3 part mold; i. e. the mold seam goes around the insulator high

on the dome. The others are what is normally thought of as 3 part mold which

I'll call new 3 part mold. One cannot accurately date Hemingrays this way though

as there appears to be quite an overlapping period when both mold styles were

used.

There may have been some 2 part mold Hemingrays (the picture accompanying the

Dec. 19, 1871 patent shows a 2 part mold insulator of the Brookfield WUT style),

but as of this writing I don't know of any.

Hemingray embossing differs from Brookfield in that the numbers refer to the

styles, and letters designate lot numbers. A signal then with the 1871 patent on

one side and a 2 on the other is a Hemingray 2. One can be reasonably sure this

is correct because the number 4 Dec 19 1871 for instance was later embossed

Hemingray 4 (see numbers 4A and 4B on the list).

One other Hemingray feature is the flat collar at the base of the screw

threads which was included in the Hemingray patent. According to the patent the

insulator was formed by first pouring a quantity of glass into the mold. Next a

floating plunger was pressed into the mold pushing the molten glass around it

thus forming the insulator. When the glass reached the right height in the mold

the screw mandrel formed the threads through a hole in the bottom of the

plunger. This plunger, because it could be pushed to any given depth compensated

for too little or too much glass in the mold.

ABOUT THE LIST

The list contains only insulators I have seen and consists of the following:

- An identifying number which corresponds with a drawing (drawings appear at

the end of the list).

- Woodward's CD number if any.

- Embossing (a slash / means a new line, F means front, and B means back).

- Color

- Type of mold

- Rarity

- Additional comments

Rarity is a combination of scarcity and other appeal and is as follows :

Rarity 1 - Value over $20

Rarity 2 - $15 to $20

Rarity 3 - $10 to $15

Rarity 4 - less than $10

It should be remembered that these are one person's opinions only and by no

means an absolute price guide.

LIST

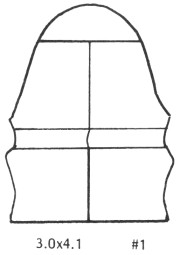

| 1. |

Hemingray 1 no CD number

F on dome PATENT/Dec 19 1871

B on dome 1

Color: aqua, green

Old 3 part mold

Rarity 1

This is the classic Hemingray. Not only is it old and scarce but it also

has an uncommon shape. I have seen an unembossed version of this

insulator which could also be Hemingray. |

|

| 2. |

Hemingray 2 CD 132

F on dome PATENT/Dec 19 1871

B on dome 2

Color: green, light SCA

Old 3 part mold

Rarity 2 |

|

| 3A. |

Hemingray 3 CD 133

F on dome PATENT/Dec 19 1871

B on dome 3

Color: Green

Old 3 part mold

Rarity 2

This varies from #2 in that it is shorter, lighter (weight) and the dome

is more rounded. |

|

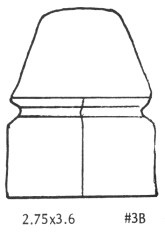

| 3B. |

Hemingray 3 similar to CD 133

F on skirt PATENT/Dec 19 1871

B on skirt 3

Color: green

New 3 part mold

Rarity 3

This appears to be a later version of #3A. |

|

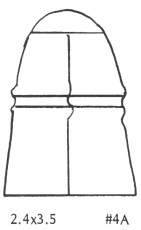

| 4A. |

Hemingray 4 similar to CD 124

F on dome PATENT/Dec 19 1871

B on dome 4

Color: aqua

Old 3 part mold

Rarity 2 |

|

| 4B. |

Hemingray 4 CD 124

F on dome PAT Dec 19 1871

F on skirt 4/PATENT/May 2 1893

B on skirt HEMINGRAY/No 4 Color: aqua

Old 3 part mold

Rarity 2

This is an interesting one as it represents a transition from old to

new. The 1893 embossing is crooked, and it looks as though it and the

drip points were added after the original molding |

|

| 4C. |

Hemingray 4 CD 124

F on skirt PATENT/MAY 2 1893

B on skirt HEMINGRAY/No 4

Color: aqua

Old 3 part mold

Rarity 4

This one completes the transition from old to new. |

(see above) |

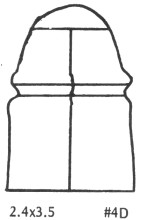

| 4D. |

Hemingray similar to CD 124

F on dome PATENT/DEC 19 1871

B on dome 4

Color: yellow green

Old 3 part mold

Rarity 2

This differs from #4A in that it has a longer skirt and different wire

groove. |

|

| 5A. |

Hemingray 5 CD 120

F on dome PAT DEC 19 1871

B on dome 5

Color: aqua

Old 3 part mold

Rarity 2 |

|

| 5B. |

Hemingray 5 CD 120

F on skirt PATENT/DEC 19 1871

B on skirt 5

Color: aqua

Old 3 part mold

Rarity 3

This is probably a later version of #5A. |

(see above) |

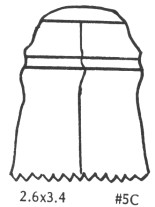

| 5C. |

Hemingray 5 CD 120

F on skirt PATENT/Dec 19 1871

B on skirt 5/PATENT May 2 1893

Color: aqua

Old 3 part mold

Rarity 2

This is another transition piece with both dates. |

|

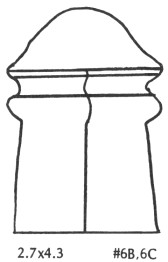

| 6A. |

WU5A CD 125

F on skirt PATENT/DEC 19 1871

B on skirt W U/5/A

Color: yellow green

New 3 part mold

Rarity 3

The A is probably a lot number. The W U in all likelihood stands for

Western Union. |

|

| 6B. |

WU5 or WU5B similar to CD 125

F on skirt PATENT/DEC 19 1871/B

B on skirt W. U./5

Color: aqua

New 3 part mold

Rarity 4

This looks like an improved version of the W.U. 5A. It has a larger wire

groove. |

|

| 6c. |

WU No 5 similar to CD 125

F on skirt PATENT/May 2 1893

B on skirt HEMINGRAY/W.U. No 5

Color: aqua

New 3 part mold

Rarity 3

This is the same insulator as #6B except there are drip points on this

one (not shown in drawing). |

(see above) |

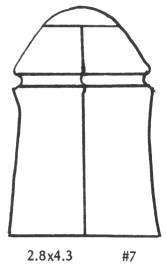

| 7. |

W E Mfg. no CD number

F on dome W. E. MFG. Co.

F on skirt PATENT/DEC 19 1871

B on dome W. U.

Color: various greens

Old 3 part mold

Rarity 2

Western Electric went by the name Western Electric Mfg. Co. at this time

so this could well be what the W. E. stands for. |

|

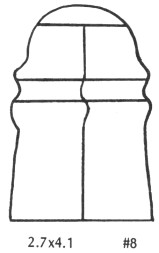

| 8. |

A. U. similar to CD IZ5

F on dome PATENT/DEC 19 1871

F on skirt A. U.

Color: aqua Old 3 part mold

Rarity 1

A. U. stands for American Union. I know no more about this unit except

that it is quite rare. |

|

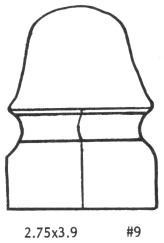

| 9. |

CD 134

F on skirt PATENT/DEC 19 1871

Color: light aqua

New 3 part mold

Rarity 4 |

|

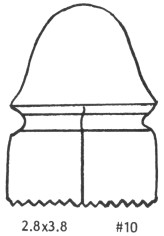

| 10. |

CD 134

F on skirt PATENT/DEC 19 1871

B on skirt PATENT MAY 2 1893

Color: aqua

New 3 part mold

Rarity 2

Here is another transition insulator. The 1893 patent is off center and

appears with the drip points to have been added later. |

|

FINAL COMMENTS

This report has not attempted to answer all questions on early Hemingrays.

As a matter of fact it quite probably raises more than it answers such as :

- Are there Hemingray 6's and 7's? Tibbitts lists a Hemingray 8 with only

the 1893 patent.

- Were there WU 1's thru 5's?

- Are there 2 part mold Hemingrays ?

- What was the American Union (No. 8)?

I've attempted to tie together some of the known facts and also to propose

a few new ideas. If it's generated interest in early Hemingrays, it has been

well worth the effort.

|