CD162 H.G.CO. - Embossing In Transition

by Gary Kline

Reprinted from "Crown Jewels of the Wire", August 1998, page 10

Part I

I had been collecting H.G.CO. and Hemingray signals for their color for a few years when

I decided to arrange my shelves according to their embossing styles just to see how many different types I

had. I started out by separating the H.G.CO. embossed pieces from the Hemingray/patent date,

Hemingray/No. 19, and Hemingray/Made In U.S.A. pieces.

In the H.G.CO. pieces I noticed a distinct difference in the way H-G-CO. was engraved. I was

able to group the H.G.CO. embossed pieces into four different embossing styles. Once I had all the

embossings separated into their prospective groups I began to line them up on the shelves, oldest

embossing style to the newest.

(Cover Photo)

After getting the signals arranged in their proper order I stood back to look at the collection. I was

quite amazed at the results. Although I had a lot of H.G.CO. embossed pieces, only one embossing style

had any color to speak of in it. In the other three embossing styles of H.G.CO. signals, I had very few

examples and most of the colors were varying shades of aqua.

After seeing my collection this way I began to wonder just how many embossing varieties there

were. I also wanted to know all the colors that were made and if any embossing or manufacturing errors

were produced.

To find out this information I sent a survey to about forty H.G.CO. signal and Hemingray

collectors around the country. The survey dealt just with the signals having the H.G.CO. embossing. I

listed the varieties I had in my collection and asked the collectors to list any new varieties and colors that

they had in their collections. Information as to drip point count, embossing errors, and manufacturing

oddities like milk, bubbles, and amber swirls was also asked for.

The response was great with almost all the collectors returning their surveys. Represented in the

surveys were nearly 500 different H.G.CO. signals. This gave me a solid base of information which I

charted under four main embossing headings.

If you’ve ever done research like this before you know how one can start

out with an idea and direction and as the information comes in you find that you

have to redo your thinking, drop some ideas, and make adjustments as the facts

come in. This project has been no different. After four years of gathering

information I’m still finding out new things about these early Hemingray

signals. Without any Hemingray archives as to mold and insulator production from

this period, compiling some of the material has been painstakingly slow. The

insulators themselves have been the best tellers of their story, holding their

history in their glass form. The only draw back is that hundreds of examples

have had to be collected and analyzed in order to dispel or prove certain

theories of just what was going on with signal production around the turn of the

century.

The main information that I will share with you deals with how to tell the

embossing style of your H.G.CO.’s. This is the key to understanding the

production time line of the signals with the H.G.CO. embossing. Along with that

I will list the embossing errors, known colors, and all pertinent information

for that style.

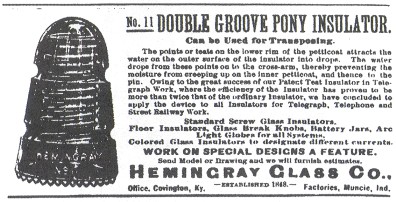

A little about color before we go on. Hemingray in an early 1900’s

advertisement offered “Special colored glass insulators” to the trade.

Hemingray was prepared to furnish Red, Blue, and Amber glass in all styles of

insulators. They also stated that “All insulators are furnished regularly and

carried in stock only in green glass, and green glass will always be shipped

unless otherwise specified.”

Hemingray and his customers obviously did not look at insulator color the

same as we collectors do today. Today’s collector looks for many subtle

differences in the hue of an insulator. This is most noted in the amber and aqua

colored signals. I did not try to split fine hairs on color but listed the ones

most recognized and used by signal collectors today. For more information look

in McDougald’s Price Guide under the heading “COLOR”. Behind each color

listed you’ll find a number which gives its relative rarity rating within that

particular embossing style. The numbers are on a scale of 1 to 10 with the lower

numbers being the most common. This will give you an indication of what

generally is the easiest to most difficult signals to find for that

embossing.

It is my hope that you will find this information useful in your collecting

and understanding of H.G.CO. signals and that you will use the terms for the

embossings in your communications with other collectors. I think you will see

that there is a little more to CD 162 H.G.CO.’s than just brightly colored

glass.

Catalog p 584 from Electric Appliance Company,

1909-1910 (Courtesy of Elton Gish)

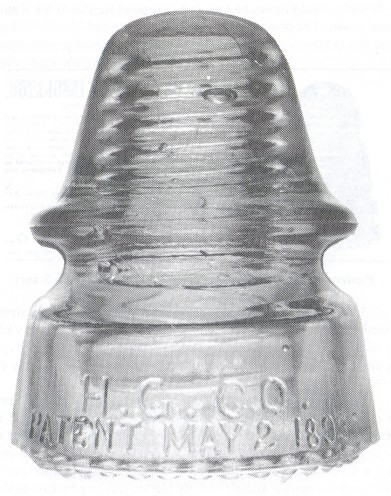

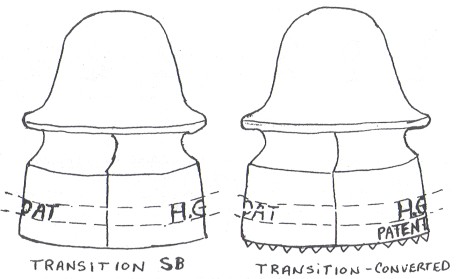

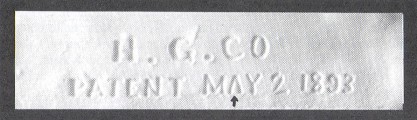

“TRANSITION” EMBOSSING

The earliest signals that Hemingray produced used molds that incorporated

hand engraved letters. Many collectors have referred to this style of lettering

as “Covington”. This is in reference to the early Hemingray factory in

Covington, Kentucky where some may have been produced. The describing of these

particularly embossed insulators as “TRANSITION” embossed has been used by

many collectors for about the last five years. One of the reasons is because the

word “TRANSITION” reflects the move of Hemingray’s production from

Covington to the Muncie factory in the late 1880’s. We’ll see the other

reason why they are labeled Transition later on. The Transition style embossed

insulators are characterized and identified by the way H.G.CO. and PETTICOAT are

engraved.

Typically the letters are large and well spaced. Engraving was done by hand

and depending on the mold, will show varying degree of crudeness. (NOTE:

“PATENT MAY 2 1893” is not used to identify any engraving style. Only the

letters H.G.CO. and PETTICOAT are used.

Some other Hemingray insulators that have used the same style of engraved

letters and were produced around the same time are the earliest CD 145, CD 151,

CD 160 and CD 164’s. They also have the same H.G.CO. PETTICOAT embossing.

Although we can’t pinpoint an exact date of production we can come up with a

range based on the design patents used at the time.

One of the most effective and practical design improvements of the 1880’s was

that of the double petticoat by Samuel Oakman which was patented on November 13,

1883. The design of an inner skirt or petticoat aided in keeping the screw pin

dry, making for a more efficient insulator. Insulators made by Brookfield and

others embossed this patent date on their insulators when incorporating the

design. Hemingray was obviously able to legally use an inner skirt design but

touted his insulators with a bold “PETTICOAT” on one side. On the other end

of the time spectrum, these insulators with the early engraved embossing were

all made with smooth bases which places them before Hemingray’s drip point

patent of May 2nd, 1893. Based on this, the earliest smooth based H.G.CO.

signals were made from the late 1880’s to just shortly after 1893. A span of

some six to nine years.

Transition Smooth Base

Even though we have a possible production span of around six years, the

smooth based H.G.CO.’s seems to have seen a relatively small production during

this time when compared to the CD 145 and CD 151 H.G.CO. The railroads great

expansion and laying of track and telegraph lines during the 1880’s surely had

an influence on Hemingray and what they produced. CD 145’s and CD 151’s were

the choice insulators of railroads for their telegraph lines, and millions were

needed. On the other hand, power companies and electric street railways which

were just in their infancy, used the CD 162 for their circuits. It would be a

few more years before the full brunt of the industrial revolution and electrical

powering of America would create a more substantial demand for the CD 162.

Let’s deal with some examples of the H.G.CO. smooth base Transition

embossings that you will find.

In the years I’ve been collecting signals I’ve been able to gather

examples of fifteen different smooth base molds. I haven’t found any new mold

examples in the last two years but I’m still looking and comparing pieces in

case a new one would pop up. Telling them apart is quite easy. I use the spacing

of the letters and location of periods in relationship to the letters in

comparing them. Most useful though for comparing molds are the hand engraved

letters. They are like fingerprints, each with its own set of unique

characteristics. I suspect that maybe more than one engraver was employed in

making these molds by the different ways certain letters were formed.

This unique mold has a serif on the "C".

In the lettering of H.G.CO. you will find it with and without a period after

“CO.” The ratio of molds are 2 to 1 with ten having a period after “CO.”

and five without a period. The size of the lettering varies slightly which would

lead one to classify them as having either small or large letters.

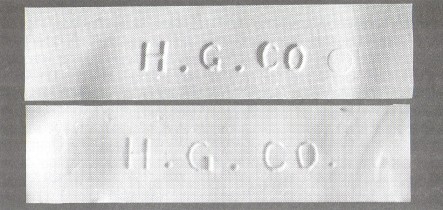

Transition H.G.Co without and with period after "CO".

No errors have been noted in regards to the spelling of H.G.CO. or PETTICOAT.

Dome letters exist in the following: Dome letter “A”, three molds. Dome

letter “O” two molds. And finally one mold has a dome letter that looks like

a “C” that’s almost closed. At this time collectors generally do not give

value to the absence or inclusion of a dome letter or period after

“CO.”

One noted oddity and puzzlement that the H.G.CO. smooth base series has is

the piece with the so-called “134 dome”. This insulator incorporates the

base of a CD 162 with a dome having the contour and size of a CD 134.

(LEFT) CD 162 with conventional dome.

(RIGHT) CD 162 with "134" dome.

Until just recently I thought that these were a completely separate product and

mold from the CD 162’s. Through the help of fellow collectors I was sent three

examples to examine. The three examples’ engraving showed that they were made

in different molds. To my amazement I was able to determine that the bottom

halves of the molds matched up identically with three normal smooth base molds

that I had.

The tops were a different story. One of the “134” domed

pieces had the dome letter “A”. This may be a key bit of evidence in finding

out if old CD 134 Hemingray dome molds were used. Because of the engraving, the

dome letter has a unique “fingerprint” that one should be able to match up

with a counterpart “normal” CD 134 or CD 162.

Obviously some retooling of the molds had to take place in the

conversion from “134 dome” piece to the normal style. Logic would dictate

that the “134 dome” would have been made first before converting it into the

conventional smooth base we think of. In the mold, extra metal would be need in

the wire groove area to form the “134’s” open, sweeping arc. If desiring

to make a normal CD 162 they could easily retool the mold to remove metal in the

wire groove area. This would also form the more prominent upper wire ridge.

Wire groove of CD 162 (LEFT) compared to

CD 162 with "134" dome (RIGHT).

It would appear that the H.G.CO.’s with the “134 dome” were made first

and then transformed into “normal” 162 smooth bases. Whether this production

came early on or toward the end of making smooth base molds is unclear. Why were

they made, where were they used, and how this hybrid came into being are just

some of the questions that are raised.

Hemingray produced H.G.CO. smooth base insulators in a wide array of colors.

Rarity of some of these colors make these signals a challenge to collect. Basic

colors are Aqua, Blue, Green, Amber and Purple. Below are listed all know shades

of these basic colors. All colors except for the aqua, Ices, and tints are

mildly difficult to nearly impossible to come across. Purple is the noted rarity

in the smooth base CD162 H.G.CO.

SMOOTH BASE H.G.CO. COLORS

| CLEAR (8) |

GREEN AQUA, LIGHT (1) |

AMBER, YELLOW (8) |

| AQUA, LIGHT (1) |

GREEN AQUA (2) |

AMBER, DK.YELLOW (7) |

| AQUA (1) |

GREEN, TINT (1) |

AMBER, LT. ORANGE (4) |

| AQUA, DARK (2) |

GREEN, ICE (1) |

AMBER, DK. ORANGE (4) |

| BLUE AQUA, LIGHT (1) |

GREEN, LIGHT (2) |

AMBER, DARK RED (8) |

| BLUE AQUA (1) |

GREEN, LIGHT LEMON (3) |

AMBER, GOLDEN (5) |

| BLUE, TINT (1) |

GREEN, LIME (5) |

|

| BLUE, ICE (2) |

GREEN, DEPRESSION (8) |

|

| BLUE, LIGHT (3) |

PURPLE, LIGHT (9) |

|

| BLUE, HEMINGRAY (5) |

PURPLE (10) |

|

| BLUE, PEACOCK (6) |

|

|

| BLUE, PEACOCK DARK (6) |

|

|

In the CD162 with the “134 dome”, known colors are basic and pieces seem

to be limited in number. Colors are: Light Blue Aqua, Blue Aqua, Aqua, and Green

Aqua.

“TRANSITION” EMBOSSING - CONVERTED MOLD

“Transition -- Converted”

The next change in the CD162 H.G.CO. embossing occurred during the time of

Hemingray’s May 2 1893 patent for drip points. Let’s look at Hemingray’s

patent and business practice for a minute to see how they affected insulator

production and embossing during that time.

We know from Hemingray’s letter of Patent May 2 1893 that his intent was to

make an insulator with drip points attached to the bottom so that water would

shed more easily from the insulator. There seems to be some debate as to whether

the design had any merit or not among the experts of the time. But one merit of

the drip point design that’s hard to dispute is that it acted like a

trademark, distinguishing his insulators from his competitors. Hemingray, I

believe, knew what he had with his drip point design in that respect and set out

to exploit it. All of his insulators that could, would be produced with the drip

points and May 2 1893 patent date.

Western Electrician, May 11, 1895 (Courtesy of Bob Stahr)

Saturation and visibility seemed to be the marketing strategy. Prospective

insulator buyers would be bombarded with Hemingray advertising all touting the

wonderful drip points. When you saw or thought of drip points you would think of

Hemingray insulators. Who today could deny that the drip points in that respect

didn’t work as intended.

Besides having shrewd business sense in developing and marketing a new

product, Hemingray exhibits the trait of being frugal at it. Hemingray, instead

of creating whole new molds with the patent date, chose to recycle the old ones

already on hand. Besides the savings in money, a savings in time could also be

realized as the product would be able to reach the market sooner. Many Hemingray

production molds of that time were converted, not just the H.G.CO. embossed. An

example of some would be the earlier molds with Hemingray’s DEC. 19 1871

patent date like CD 120 and CD 134.

Changing the existing CD162 smooth base molds was a fairly easy process. Just

engrave the patent date where it would fit and add a prepared base mold to form

the drips was all that was needed. Because of this state of transformation in

the smooth base molds you can understand the other reason for collectors giving

them the name “Transition”. I like to use the term “Converted Mold” in

distinguishing these pieces from their smooth base brothers because it conveys

more fully how these insulators came into being. Although one could just as

easily convey the same meaning by using the terms Transition SB and Transition

SDP.

I was curious about the number of CD 162 smooth base molds that were

converted during the May 2 1893 patent. To find this out I would have to locate

as many different smooth based and converted signals as I could and start

matching them up into mold sets. Once I had the pieces, matching them up was

rather easy. Since they came from the same mold I would use the spacing and

“fingerprints” of the engraved H.G.CO. letters to match them with each

other.

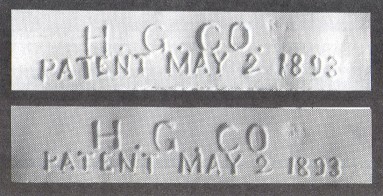

Converted Mold Set

sagging bar in “H” top of “G” short

crease at top and dimple at bottom of “O”

Finding these mold sets has been a challenging task. To date a total of

fifteen different smooth base molds have been identified. Of the fifteen smooth

base molds, I have examples of twelve that were converted with the patent date.

I believe that a few of the molds were not converted to accommodate certain

customers needs in wanting smooth based insulators. You can see the same desire

of customers wanting smooth based signals taking place with the various lines of

Hemingray embossed CD 162’s in the years that would follow.

Converted Mold Set

sagging bar in “H” top of “G” short

crease at top and dimple at bottom of “O”

Let’s look at some of the features of the converted mold signals that are

used to identify them. Keep in mind that these all have exactly the same

features as their smooth base counterparts except for the added patent date and

drip points. You will see these have the same dome letters, with and without

periods after “Co”, and pronounced upper wire ridges that are so typical of

the smooth base signals.

When the smooth base mold was produced there were no thoughts of a patent

date being added. The engraved letters were positioned and centered on each mold

half so “H.G.CO. and PETTICOAT” mirrored each other. Turning an insulator to

read the embossing, you’ll see the letters H.G.CO. on the same linear plane.

In the Transition Embossing,

“H.G.CO.” and “PETTICOAT”

are placed on the same linear plane.

All Converted Mold patent dates are in close

proximity to “H.G.CO.” On some molds, the letters

are so close that they actually touch.

When the mold was converted the patent date was placed below H.G.CO. most

often resulting in a cramped fit. The spacing was so close that some of the

letters actually touched each other. A few of the molds are a little more

forgiving with their space.

One of the more interesting features of the converted mold signals is the

styling of the engraved numeral “2”. Unlike the numbers “1893”, the

number “2” lent itself to the artistic expression of the engraver. In the

twelve converted molds each of the engraved twos is slightly different but can

be categorized into two basic styles. The styles are identified by how the base

of the two is formed.

Styles of numeral “2”

“Rockinghorse” base “Dash” base

I’ve noted no lettering errors except that in two of the molds the cross

bar in “A” of May is missing. I believe this was an intentional omission on

the engraver part for some reason. Not only is this cross bar omission seen in

the H.G.CO. CD162 , but in other H.G.CO. products of the time like CD 151 and CD

133.

No Crossbar in “A” of “May”.

Of all the CD162 H.G.CO. Patent May 2 1893 embossing styles that we will look

at, the Transition - Converted signals are by far the most difficult to find.

After years of producing smooth based insulators these converted molds were

approaching the end of their useful life. Production was probably limited to a

only a year or two. (1893-1895 est.)

Getting these insulators without any damage is a challenge. The pronounced

upper wire ridge lent itself to chipping. The new drip points were a source of

much damage too. In drilling the mold area for drip points they got carried away

on some, drilling them too deep, forming long cylindrical drips instead of

little cones. Also they didn’t drill enough of them. This left each drip more

prone to damage. Drip counts for these average in the 31 to 35 range. Glass

quality may be a factor in some of the insulators as they have a fragile feel to

them. Of course, some just saw more than their fair share of rough

handling.

Colors are rather limited in the Transition-converted signals. Most commonly

found are colors in the varying shades of aqua with the lighter shades being

found the most. Ice colors and tints are very scare. Vivid greens are rare as is

the case with all the other CD162 H.G.CO. embossing styles. Colors normally

associated with H.G.CO. signal production are lacking in this embossing, namely

Peacock and Purple.

Transition-Converted H.G.CO. COLORS

| CLEAR (9) |

GREEN AQUA, LIGHT (2) |

| AQUA, LIGHT (1) |

GREEN AQUA (2) |

| AQUA (1) |

GREEN, TINT (5) |

| BLUE AQUA, LIGHT (2) |

GREEN, ICE (4) |

| BLUE AQUA (1) |

GREEN (8) |

| BLUE, TINT (6) |

GREEN, SAGE (5) |

| BLUE, ICE GREY (5) |

GREEN, FOREST (10) |

| BLUE, HEMINGRAY (3) |

GREEN, YELLOW (10) |

| BLUE, CORNFLOWER (10) |

AMBER, ORANGE (4) |

| SCA, PINK TINT (7) |

AMBER, RED (7) |

| SCA, SMOKE TINT (7) |

AMBER, OXBLOOD RED (7) |

| |

AMBER, DARK OLIVE (9) |

One final thing to note in the Transition embossed smooth base and Converted

Mold signals is the absence of pieces being reported with amber swirling, snow

and bubble storms, or major milk.

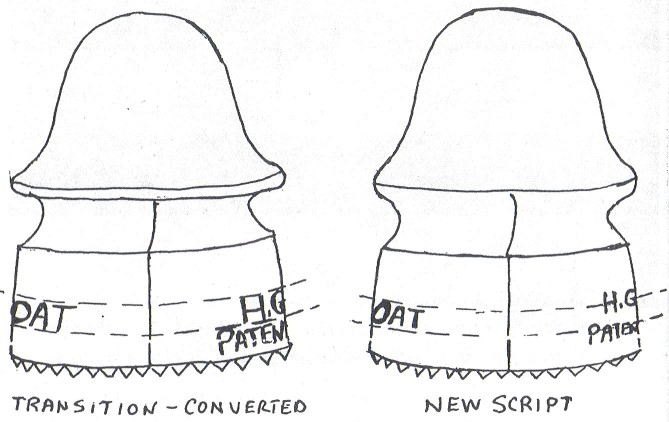

“NEW SCRIPT” EMBOSSING

“New Script”

Sometime during the production of the Transition-Converted CD162 H.G.CO.

signals, Hemingray moved to produce a new line of molds that would take the

place of the aging converted molds. The new line of molds incorporated script

style engraved letters like the Transition did. But now the letters were more

refined, had closer spacing, and were uniform from mold to mold. Proper spacing

between H.G.CO. and the patent date was now allowed and gone are the days of

cramming the patent date in to fit. The embossing style used in these molds is

referred to as “New Script”.

Besides the embossing, another area of the mold saw refinement too. The wire

groove area was reshaped slightly, reducing the pronounced upper wire ridge and

making the wire groove more open. The redesigned shape would add strength in the

upper wire ridge making it more resistant to chipping. The open shape also

allowed the insulator to accommodate a wider range of wire diameters.

(Left) Transition-Converted.

(Right) New Script

Notice the more open wire groove of the new script.

These new molds were not likely used in conjunction with the old converted

molds. Once they arrived at the factory the old molds would have been retired.

The color and quality of the glass produced seems to bear this out. The colors

are quite different in the New Script versus the Transition Converted. Even in

the common colors like aqua, glass quality and tint is noticeably different.

Medium to light shades of aqua prevail in the Transition-Converted, where as,

Medium to dark shades of Aqua are the rule for the New Script. The New Script

also saw the production of Peacock, Orange and Red Amber colored signals that

have a florescent quality. Collectors refer to these signal as “Glowers”.

Amber wisps and bubbles are now seen frequently in the glass of these signals.

Estimated production years for the New Script molds are 1895 to 1898. A

different style of embossed H.G.CO. signal that we will examine later, was most

likely used along with the New Script. This new mold style would have been

incorporated as orders and production demands for the signals increased. Glass

color and quality are nearly the same for these two styles.

Although the New Script molds use a script engraving similar to the Transition,

let’s look at the features that make them different. Keep in mind that these

are new molds unlike the old Transition that was converted.

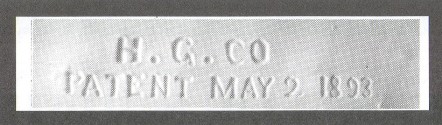

On the front half of the New Script molds proper spacing was allowed in

between H.G.CO. and PATENT MAY 2 1983. The result of this is that H.G.CO. is

positioned slightly higher up on the mold, allowing the patent date to fit with

ample room. Turning an insulator to view the mold line we see that H.G.CO. is no

longer on the same linear plane as PETTICOAT. This effect is noticeable more on

some molds than others.

On the New Script molds, “H.G.CO.” is now positioned on a

higher linear plane than “PETTICOAT.”

(Left) Transition-Converted (Right)

New Script

Looking at the letters H.G.CO. you’ll notice that they are spaced close

together. Also you’ll see that the letters are relatively small, neat, and

have a rounded appearance to them. This engraving characteristic was applied to

every New Script mold with amazing consistency. Also in keeping with this

uniformity, the period was omitted after “CO” on all the molds. The styling

of the “2” was also consistent. All of the molds have “Dash” based twos

except for one mold which has the “Rocking horse” style.

“Rockinghorse” Base “2”

“Dash” Base “2”

In the New Script, only one mold used

the “Rockinghorse” base “2”.

All other molds used a “Dash” base “2”.

The only lettering error or exception to note is one mold that

lacks the cross bar in the letter 'A" of MAY.

Cross bar missing in “A” of “MAY”.

I’ve been able to locate ten different molds of the New

Script. Even though that is a lower number of molds than the Transition, they

seem to have seen greater production. Examples of the New Script embossed

insulator can more easily be found than their Transition counterparts.

Let’s look at the colors of the New Script signals that you

will come across. Aqua is the most commonly found color. Ice colors are very

scarce in this embossing. Again, vivid Greens are rare. If you’re looking for

a glowing Peacock, glowing Orange Amber, Oxblood Red Amber or super bubbly

signal; the New Script embossing is where they are most easily found. Finding

VNM to MINT examples in the New Script is much easier than the Transition

Converted.

NEW SCRIPT H.G.CO. COLORS

| AQUA, ICE (7) |

GREEN AQUA, LIGHT (2) |

AMBER, ORANGE (4) |

| AQUA, LIGHT (2) |

GREEN AQUA (1) |

AMBER, RED ORANGE (3) |

| AQUA (1) |

GREEN, LIGHT (8) |

AMBER, OXBLOOD (6) |

| AQUA, BUBBLY (4) |

GREEN (9) |

AMBER, DARK OXBLOOD (7) |

| BLUE AQUA (2) |

|

|

| BLUE, PEACOCK (3) |

|

|

| BLUE, MILKY PEACOCK (7) |

|

|

- - - - - - - - - - -

Gary Kline will be covering the Prism and Stamp embossing styles on Hemingray

signals in an upcoming article.

|