Porcelain Insulator News

by Jack H. Tod, NIA #13

Reprinted from "INSULATORS - Crown Jewels of the Wire", October 1979, page 22

Gerald Brown (Colorado) didn't believe me when I said my

crystal ball indicated he'd better take a big supply (a very big supply) of his

new book to the Denver N.I.A. Convention. He had people waiting in line to

obtain the book until he sold out the "big" supply he took with him,

and then he just started taking addresses to mail copies to those who weren't

nimble enough to get in line quick enough.

I doubt that the book will be

reprinted when the supply is exhausted. If you miss out getting a copy of the

book, don't say I didn't warn you!

Jack

Jerry Turner of Goshen, Ohio (Past

Pres., N.I.A.) sent a newsy letter to bring us up to date. Both Jerry and

Marilyn have changed positions in the fall of 1978. Jerry is now with Durocraft

Products Inc., Cincinnati (Manufacturing, V.P. of Sales). Marilyn is chief of

quality control section of a machine shop only two miles from the Goshen

homestead. The rest of the family are all doing fine.

Jerry mentioned a list of

goodies he's obtained in the past year, and it makes one drool.

He acquired

another U-709A Pittsburg with an incuse hand-stamp marking, but this one has a

type face resembling a fancy Old English, something like we've sketched above --

uite different from the other marked Pittsburgs reported in the past.

I'm sure this was a welcome addition for Jerry, since he's always been a real

collecting fan of Pittsburg porcelains.

Another interesting item Jerry got at

the Friendship, Indiana flea market is a pottery canning jar with the marking

shown at the right (jar bottom).

Gerald Brown told me about eight years ago that

when he was researching Illinois Electric Porcelain Co., Macomb, Ill. he had

learned there had been at least two other "potteries" there in the

past. Here's proof of the pudding. Although not connected in any way (that we

know of!) with insulators, this jar is a nice shelf item for anyone interested

in Macomb items.

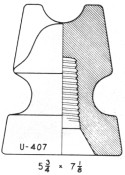

Jerry also said that it was hard to believe, but he

counted six porcelain U-407 Jumbos in the exhibits and on sales tables at the

10th N.I.A. National Convention in Denver (July 1979). This U-407 is not a rare

item still, but it does show how many goodies do make their appearance at the

annual N.I.A. National.

Jerry also acquired another U-407 with the LOCKE

handstamp marking at the Washington Court House (Ohio) flea market. This came

from a friend there who had obtained it in a collection he bought in

Pennsylvania. Trying to corner the market, Jerry?

Jerry got a brown U-944 at the

Denver show. This is an early classic glazeweld by THOMAS. It's a rare item in

white glaze, and even rarer with brown glaze.

Then there was a cute little U-442

made by Pittsburg (specimen unmarked). This was a big surprise to both Jerry and

me. We've collected Pittsburg items for a long time, not to mention many

weekends of digging in the old Pittsburg factory dumpage, but this is really

something different for Ptsbg. We never dreamed they made small cables such as

this one.

These are probably just the goodies Jerry told me about. No telling

what else he's holding back on us!

Jack

Two more Pittsburg "date

control" markings have been reported since our request in July 1979 CJ for

help in trying to solve the date coding puzzle. Both markings were on P.R.

"hat" distribution insulators.

Jack Gooden, Jr. (Medford, N.Y.) has

one with a marking of "JUL 26 ANS'D" on the dome.

Ben Kirsten (Grand

Junction, Colo.) has a similar one with "AUG 12 REC'D" on the

dome.

We're getting very close to having enough of these date stamps to crack

the year coding used by Pittsburg. If just several of you can jot down on a

postcard the datestamp marking on your Pittsburg specimen, we may have success

in this venture. Please??

Jack

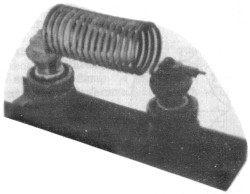

Dear Jack:

The enclosed picture is of an

item I found a while back. I thought it might be of interest to CJ readers who

collect the insulator go-with item.

It was described to me as a "choke

coil". The idea was to mount it on the crossarm and connect it in series

with the primary wire so the line current would flow through the coil (normal

current up to the nameplate rating of 50 amps). When the current exceeded the

rating (as with lightning), the current flowing through the coil produced a

field which opposed this flaw, thereby "choking" or reducing the

transient current peak.

I am not positive that this was the correct way in which

these units were used., but I have never seen any in service anywhere, so I

can't disagree. If you have any more information (correct use, date of use,

value, or whatever), I would be interested in finding out.

The whole assembly is

constructed on a piece of 3" channel iron 17" long. The large coil is

3" outside diameter and made of AWG #2 copper wire. The husky terminals are

cemented into the pin holes of a pair of ordinary pin type porcelains attached

inverted to the base. Riveted to the side of the channel iron base is a

nameplate reading as follows:

ELECTRIC SERVICE SUPPLIES CO.

PHILADELPHIA - NEW

YORK - CHICAGO

TYPE LU No.50457 VOLTS 3000 AMP 50

Frank Shore

Tucson, Arizona

- - - - - - - - - - -

Dear Frank:

I don't have an answer for what this very interesting

"gismo" is, but maybe one of our elder linemen or electrical engineers

out there can write and tell us. One thing for sure is that it must be a real eye-catcher

sitting there with your insulator collection. I can't make a guess as

to "value" of any such oddball items that turn up out of the blue.

Their value depends on the combined thoughts of both seller and buyer -- if a

transaction does take place.

I can't guess its vintage, but E.S.S. Co. was in

business from 1906 until at least the 1930's. Woodward didn't have in his book

data on this company, but I have at least some and will give it below for the

benefit of collectors of both glass and porcelain insulators.

Electric

Service Supplies Co. was established in 1906: President, Charles G. Mayer; V.P.

& Treasurer, A. H, Englund -- both formerly of Mayer & Englund Co.

(1901-1906, also of Philadelphia). I always just assumed this was the same

company with merely a corporate name change.

Knowles cable insulators were

jobbed with an embossed M. & E. Co. marking, and then later with the E. S.

S. Co. marking after 1906. The company probably jobbed porcelain pin types of

one or more companies throughout the years, but a 1928 catalog shows they were

then jobbing the complete line of Franklin Porcelain Co. insulators. Franklin

was located in Norristown near Philadelphia, and there may have been more than a

supplier-dealer relationship between the companies.

E.S.S. Co. used the word

"KEYSTONE" as a trademark (registered #65,586, 10/8/07) and also later

a keystone symbolic logo (registered #80,769, 1/31/11; reregistered #266,285,

1/14/30). Of very special interest is the trademark tie-in with the former Mayer

& Englund Co., since the registration showed "used since" dates

from 1906 thru 1926 for various equipment, plus the conspicuous date of 1901 for

"Trolley Insulators etc." [Was the M &, E Co. address also at 17th

& Cambria Sts. in Philadelphia??]

The E.S.S. Co. main office and factory was

located at 17th & Cambria Streets, Philadelphia, Pa. (Don't all you dump

diggers get there the same weekend!). They had sales offices in six other U.S.

cities plus three in Canada.

Other than that, I know nothing more about the

company.

Jack

HELP!

Does anyone have an old catalog of Virginia Pottery Co., New

Lexington, Ohio?? I know they exist, because someone told me a number of years

ago they'd seen one in the hands of another collector. If so, can we merely

borrow it to make prints. If you don't trust to mail it, then I'll pay your

costs in making Xerox prints of the pages and mailing them.

I am also very

anxious to locate any copies of catalogs issued by THOMAS before 1900, and

especially any pre-1896.

I would very much like to hear from anyone who has

catalogs or access to trade journals with drawings, photos, sketches or

descriptions of pin type insulators made before 1900 by either of the following:

Electrical Porcelain & Manufacturing Co. (Trenton, NJ); Peru Electric

Manufacturing Co. (Peru, Ind.); General Electric Co. (Schenectady, NY). I will

reimburse you for print and mailing costs if you have any such information.

Jack

Dear Jack:

Enclosed are pictures of several insulators. The first (at

right) seems to be a U-38 and has the Fred M. Locke marking an the crown. It

looks like it was machine made. The other one of similar style is a light tan

and very crudely made. The top is partially sunk in, the wire groove is not

uniform in depth or width, its base has been "ground off" so it sits

crooked, and it is 1/4" shorter than the other one. This insulator is so

crude you would think it was made by hand. I got it at a flea market for $.25.

The other insulator (at right) seems to be a U-239 [No. it's a U-236, JHT]. I

found six of these in as many shades of brown including one light buff and one

olive drab.

These insulators were on an old telephone line that ran from the old

Headlight Mine on the Trinity River in Trinity, Cal. to the Altoona Mine some 16

miles to the east in steep country. Both mines were operating in the 1870's and

later. The telephone line was put in about 1916.

Can you give me any info on

these insulators? I don't collect porcelains, but I pick up every insulator I

see when I am out looking for the McLaughlin glass insulators I do collect. I'm

a native Californian, and I think the McLaughlin glass is the prettiest of the

West Coast glass.

Royce Hensley

Redding, Cal.

- - - - - - - - - -

Dear Royce:

Your first two

insulators, the Fred M. Locke ponies, are both generally U-39 styles; the U-38

style is a distinctively more dainty variety of the same catalog number. There

is a wide variation in quality and manufacturing methods of these, just as your

specimens indicate.

Regarding the bases (& heights), it was general practice

then to dip the whole insulator in glaze slip and then after drying and before

firing, to prepare the base firing surface by either fettling off the unwanted

rim glaze with a course rag or a belt sander (which removed considerable body

clay). Your photos show a specimen each of both methods.

Regarding the wire

groove, these insulators were plunged (press formed) without the groove, and

thus avoiding the necessity for parting-type dies. Before the clay completely

dried, the wire groove was then cut in with a "green trimming"

machine. Wire grooves thus differ in size and depth. If the insulator didn't fit

squarely on the spindle of the trimming machine, the wire groove can be tilted

or very irregular in size around the insulator.

These U-39 specimens were

made approximately 1902-04, and they have a collector value in the area of $5

each.

The U-239 with "G" marking is a fairly good item also, $3 or so.

This "G" marking is our mystery marking in porcelain insulators. We

have some reasonable guesses as to the manufacturer, but it remains on the

unattributed list at this time. All of the styles with "G" marking are

dry press styles, and their vintage appears to be 1910-1925.

Jack

Dear Jack:

Thanks very much for the information on the Hewletts [See Sept 1979 CJ]. In

glancing again at the May 1979 issue, I noticed the top picture on page 40 shows

a "Guy Wire Breaker". I found 6 of these in that dismal swamp, and

they were being used as normal power insulators. In the middle of one side, each

one has the O-B marking. They are called "Elephant Ears" out here and

are hard to find. What is their value?

Also, the bird in the picture at the

bottom of the same page may be called a "chicken hawk" on Staten

Island, but I am afraid it is what we call a "Turkey Buzzard" down

here in Virginia.

David Turner

Virginia Beach, VA

- - - - - - - - - -

Dear David:

Those

"Elephant Ears" are actually "link strain" insulators. As

opposed to regular gay strain insulators, they are normally used as insulating

breaks when there is a large voltage potential between conductors on opposite

sides of the insulator -- as in many deadending situations. Ohio Brass Co. made

them from about 1909 up until relatively modern times. There was a very early

version with a flat rim all the way around instead of the "ball" edge

as in the rest of them. The early version is a very rare classic (only couple

known at most), whereas the common variety has a collector value of about $6 to

$10 depending on area of the country.

I am afraid the O-B catalog (plus most

collectors) call these "elephant ears" by the name "pork

livers" or "hog livers" for nicknames. But then, I'm also afraid

we call those "chicken hawks" and "turkey buzzards" vultures

out here. I'm fairly good at attributing porcelain insulators, but only if they

don't have feathers.

Jack

Dear Jack:

Enclosed is a photograph of 3

Missouri Pacific (MP) insulators. The only one not in the photo is the white

U-153. I recently completed a trade for 6 dome-marked U-153's and 2 U-610A

cables. The interesting thing is that there is a noticeable difference between

the beehives with the skirt marking or dome marking. The one with skirt marking

(center in photo) appears to be a pure U-153, but the dome-marked one (right in

photo) has a much wider wire groove and appears to be a design all by itself. I

believe the dome-marked is more common, but the skirt-marked may be scarcer than

the U-610A cable style.

I was wondering if the white beehive is skirt-marked or

dome-marked and if you know if it came in both varieties. By the way, I've been

trying to locate some "SOO" beehives and wonder if anyone has

reported any finds of them?

Jim Woods

Galesburg, Ill.

- - - - - - - - - - -

Dear Jim:

Thanks for the

photo and info. I agree with you that the two beehives are different in overall

shape. Don't necessarily consider wire groove differences, since the insulators

are pressed without the grooves, and the groove is later added by trimming the

insulator before the clay, dries. Although the grooves on yours are purposely

different (different specifications and/or use), there is normally quite a large

tolerance on groove height above rim, size and depth.

I think it's a mistake to

rank scarcity of the various MP insulators -- style, glaze, marking position, etc.

Not enough have ever been found from diversified areas to rank them. All are

scarce. I once had about a dozen of the skinny version (the typical U-153) all

from one trade, so that shoots down one of your conjectures. Some were marked on

the dome, others on the skirt, so that shoots down another one. I also once had

a couple of white ones, and I think they were the skinny version, but I can't

recall the positioning of their markings. I never paid much attention to

location or positioning of handstamp markings on porcelains.

Don't know of

anyone at present with some "SOO" beehives to swap, but hopefully one

of our readers will have an extra one and will get in touch with you.

Jack

Dear Jack:

The photo shows an insulator sent to me by a friend in central

New York state. Details are slim, since he can't remember where or how he came

by it.

I have your book "Porcelain Insulators", but can find no

mention of Fargo or a G.S. company. By chance are you familiar with either of

these names? Any information would be appreciated.

I really enjoy your new book

and find it a wealth of knowledge and a pleasure.

Roger L. Berger

P.O. Box 812,

Albany, OR 97321

- - - - - - - - - -

Dear Roger:

Your insulator is a "hanger insulator"

and is used to suspend a three-conductor line from an overhead messenger cable.

The small notches are for tie wires to retain the three cables in the three

large grooves. These and similar hanger insulators are a relatively modern

concept (and currently produced), and their use was spurred by the development

of high strength alumina-porcelain some years ago. They are popularly used in

urban and industrial areas where trees and structures severely limit the space

needed to run lines by conventional crossarm methods. I've seen these in use in

numerous cities, but mostly in eastern areas -- notably N.Y. state. Their

popularity should continue to increase, since this type of line construction can

be much more tidy and less costly than regular crossarm construction.

"Fargo" is a manufacturer of all forms of poleline hardware equipment,

but especially items related to brass or bronze as with the metal fitting on

your item. The "G.S." doesn't ring a bell with me, and I'm horribly

unlucky at matching initials to companies which merely fit the initials.

This

certainly is a spectacular insulator specimen, and you have it beautifully

mounted. Sorry I couldn't be more helpful as to manufacturer or exact vintage.

It certainly is modern -- and possibly a current product.

Jack

Dennis

McHenry (Iowa) has specialized for some time in all the insulators made by

Illinois Electric Porcelain Co., Macomb, Ill. He has recently commenced an

intensive research of all these insulators and hopes to compile a comprehensive

checklist of all the combinations of marking vs. styles, glaze colors, etc. Once

again, I say this will be possible only with the help of all collectors

reporting to Dennis data on their Illinois insulators. The results of his survey

will benefit all of us.

Of particular interest are the Triangle-M markings on

wet process items and the Illinois "map" markings with year dates. For

each one, record the U- number and glaze color. On the Triangle-M markings,

indicate the number and arrangement of the year-coding dots near the top of the

triangle, plus the catalog number (if any) shown underneath the triangle. For

the Map markings, record the year date at the top of the map and the insulator

catalog number (if any) inside the map.

For all other ILLINOIS marking types

record the marking, U- number of the insulator, glaze color. Either refer to the

marking reference numbers in "Porcelain Insulators" book, or make a

simple sketch of the marking.

This is a very worthwhile research project, and I

hope all collectors will take just a little time out to get this data into

Dennis' mail box. If you have any old Illinois catalogs, Dennis would like to

know the date of the catalog together with a quickie list of the U- numbers shown

in the catalog. Address: Dennis McHenry, Trexend, Rt. 1, Bettendorf, IA 52722.

Jack

I missed attending the N.I.A. National Convention this year in Denver, July

20-22, and that was certainly a great letdown for me. We spend most of each

summer at our mountain home in Arizona, usually alternating two weeks there with

one week at Phoenix from mid-May thru September. The back-and-forth schedule

just didn't work out to make it easy to get to Denver without stranding the

family in hot Phoenix.

Each time we return to Phoenix from the mountains, I'm

greeted with a big stack of mail, some of which are your insulator questions. My

apologies for any delays in answers to questions received during my absence.

Getting out the monthly camera-ready porcelain column copy is a tight fit in the

summer schedule, but I try to get it out regularly.

Jack

|